Th180 Transmission Manual Shift Shaft

1973 GT Manual Transmission Speedo inner cup seal transmission shifter shaft. Automatic to manual trans. Conversion How to Remove Shift Knob/Lever. AUTOMATIC TRANSMISSION SERVICE GROUP. B) Connecting rod to manual valve shifting. C) Selector lever shaft nut loose. Parking pawl.

They're actually really tough. If you look into it you'll find theres a whole pile of guys over in Aussie land that run them behind small V8's in Holdens and such. I haven't had any issues out of mine so far.running 7 or so pounds of boost on an 8v with 39's.

The only minor issue I have is dealing with it being a vacuum modulated trans in conjunction with a boosted motor. It will not shift under boost.so you have to have it in the right gear before you hit an obstacle. I've seen slight mentions of people building a manual valve body for them, but haven't seen any HOW TO's yet. I'd love to track down a trans mechanic that has worked on postal vans and might have a little more hands on knowledge that he could share.

If I need wheelspeed I typically put the tcase in hi range and put the trans in 1st and go to town. Typically this requires holding the brakes to build a little boost and then lettin her rip. They're actually really tough.

If you look into it you'll find theres a whole pile of guys over in Aussie land that run them behind small V8's in Holdens and such. I haven't had any issues out of mine so far.running 7 or so pounds of boost on an 8v with 39's. The only minor issue I have is dealing with it being a vacuum modulated trans in conjunction with a boosted motor. It will not shift under boost.so you have to have it in the right gear before you hit an obstacle. I've seen slight mentions of people building a manual valve body for them, but haven't seen any HOW TO's yet. I'd love to track down a trans mechanic that has worked on postal vans and might have a little more hands on knowledge that he could share.

If I need wheelspeed I typically put the tcase in hi range and put the trans in 1st and go to town. Typically this requires holding the brakes to build a little boost and then lettin her rip. Good to know.

From the stuff I have read the aussie trans has stronger factory internals. If shifted manually will the trans shift under boost? I have stock t-case gears and 5.29s, 37s. Not sure if it will pull hills in 4H or not.

I have a stand alone ecm so i can always program in some antilag. Hear it is horrible on the turbo though. With stock tcase gears you'll be fine in 4lo then.

I have 6.5's and 5.29s so im a little on the low side with the auto. No, the trans will not shift if done manually with the shifter. The modulator is what allows it to shift.if it doesnt see vacuum it will not allow the shift. I've been reading up on this and the other idea ive seen is possibly pulling the modulator and somehow setting it up so that it is always in the 'full vacuum' position so that when you shift it manually with the shifter it will shift.

This was going to be a curiosity project of mine, but i haven't come across a trans in the pull a part to try it out on. Transco makes a shift kit. Transtar my supplier has them.

I have a 4speed auto in my sami running 5psi and it shifts under boost all the time. I have duel cases and 6.5 in rear 5.29 r&p The 4 speed is a completely different animal. It's electronically controlled unless you have one of the full hydraulic variants. I had thought about going this route but for the price i am picking this trans and swap parts up for i couldn't pass it up.

$200 for everything. Clemsonjeep, are you running the 4x4 or 2wd version? I am curious about the intermediate shaft lenth/angle.

The rest will be fabricated (again.). You're right about the 4spd. Although if I'd given the turbo any thought prior to the trans swap I might have gone that way.

Then again I got a smoking deal on my setup too. Mine is the 4wd version. Liked the idea of the slightly longer intermediate shaft. I also like the idea of a longer intermediate shaft but for what i have into it and my current platform i have a bit of flexibility to make changes. My decision to go the 3 spd route is that i had already seen the aussie stuff even though its somewhat more durable. I had also seen the gearing advantage (auto vs.

Manual diff ratio). If it gives me issues it will get an AW4 (or variant) and dana 300. Honestly i feel like the weak point will be the transfer case. I am surprised the 5 spd is still in one piece considering it gets beat like it owes me money. Not to mention more than double power of factory suzuki 1.3 at this point. Thanks for the help folks.

Much appreciated. Good to know.

From the stuff I have read the aussie trans has stronger factory internals. If shifted manually will the trans shift under boost? I have stock t-case gears and 5.29s, 37s. Not sure if it will pull hills in 4H or not. I have a stand alone ecm so i can always program in some antilag.

Hear it is horrible on the turbo though. I've run one of these for years, they are TOUGH. Lots of hate went into the trans with no issues, this includes full rev neutral-drops. The Aussie v8 trimatic has the exact same internals as the Vitara/Tracker box the only difference was the tail housing, output shaft, shifter and thats about it. Running one in my buggy for the last 4-5 years now. Pushing it hard behind a 1.6 16V.

It moves the 37' sticky BFG's just fine. I did have mine rebuilt by a local guy that is very familiar with them as he does a lot of the postal vans. He was able to machine something down inside and add clutches to make it a 5 clutch pack instead of the normal 3. I run full synthetic amsoil ATF in mine and run it about 1 to 1 1/2 quarts over full. NO issues to date, does fine at extreme climbs and side angles without issue.

I did extend my breather vent into the engine bay with a catch can on it. I run a stock torque converter as the custom ones are high dollar. No real issues with that. Would be nice to get a custom one dialed in so I can have a better launch, but not for the money involved.

Temps like to be in the 160-180 range on these. Depending on fluid type, your safe up into the low 200's.

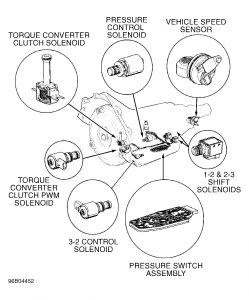

Run synthetic atf if you can. Wire the torque converter lock up solonoid to a switch if you plan on street driving it, otherwise remove it and plug the hole.

Those solonoids like to leak out of the plug end holes and well, just like to leak. Notes that I was given on these. The vacuum modulator is very important on these in regards to holding fluid pressure. I guess bad vac modulators or incorrectly working ones will let this trans burn itself up in short order. There are 3 types of 'striped' ones. Green, black and purple I think.

I don't really know the differences however. I just went with an adjustable one and let my trans guy adjust it with his pressure gauges hooked up. Run it manually. Meaning shift it into 1st, then second etc, instead of just plopping it into D and driving.

Guess the 1st gear setting uses 1st and 3rd bands and is stronger, but just in D uses the 3rd gear band only or something like that. I have it written down somewhere. I do plan on a low boost turbo in the near future, and I don't have any worries this trans will take it. I believe you will be OK with your decision. Running one in my buggy for the last 4-5 years now. Pushing it hard behind a 1.6 16V.

It moves the 37' sticky BFG's just fine. I did have mine rebuilt by a local guy that is very familiar with them as he does a lot of the postal vans. He was able to machine something down inside and add clutches to make it a 5 clutch pack instead of the normal 3. I run full synthetic amsoil ATF in mine and run it about 1 to 1 1/2 quarts over full.

NO issues to date, does fine at extreme climbs and side angles without issue. I did extend my breather vent into the engine bay with a catch can on it. I run a stock torque converter as the custom ones are high dollar. No real issues with that. Would be nice to get a custom one dialed in so I can have a better launch, but not for the money involved. Temps like to be in the 160-180 range on these. Depending on fluid type, your safe up into the low 200's.

Run synthetic atf if you can. Wire the torque converter lock up solonoid to a switch if you plan on street driving it, otherwise remove it and plug the hole. Those solonoids like to leak out of the plug end holes and well, just like to leak. Notes that I was given on these. The vacuum modulator is very important on these in regards to holding fluid pressure. I guess bad vac modulators or incorrectly working ones will let this trans burn itself up in short order. There are 3 types of 'striped' ones.

Green, black and purple I think. I don't really know the differences however. I just went with an adjustable one and let my trans guy adjust it with his pressure gauges hooked up. Run it manually. Manual wh. Meaning shift it into 1st, then second etc, instead of just plopping it into D and driving. Guess the 1st gear setting uses 1st and 3rd bands and is stronger, but just in D uses the 3rd gear band only or something like that.

I have it written down somewhere. I do plan on a low boost turbo in the near future, and I don't have any worries this trans will take it. I believe you will be OK with your decision. David You guys inspire confidence, catzuk, is yours 2wd or 4wd trans? I just finally got my buggy going with the 8v 1.6l and 3 speed auto.

I took it for a drive and it was good in 1st and 2nd but when it his 3rd it fell on it's face. Literally NO acceleration available. I am sure I will do 5.29 gears and a turbo in the future. But right now with 36' tires it is a 45mph rig only.

Also, mine does have a slight vibration from the intermediate shaft. It is almost a u-joint on u-joint.maybe a few inches of tube.

It is almost perfectly straight and it still has issues. I hope yours goes well!

TV cable is required - it increases line pressure at WOT. No need to run it up to the throttle body - I've set up a couple to the firewall so the last bit of throttle pedal travel pulls the TV cable. I may end up doing this but that area of the firewall is crowded with the turbo and downpipe there.

I think if i re-route the cable i can get it to the throttle body. I also hacked apart the stock shifter, removed interlock, ground out the reverse lockout tab so i can grab reverse and drive without pushing the button. Got rid of the plastic trim also and slid my manual shifter boot over it. I made a stubby intermediate shaft as well.

Same basic yolk to yolk similar to what you did. Mine has 5 years and lots of high speed and road miles on it and its vibration free. My flanges and yolks were in real good shape and used the higher dollar oem style ujoints in mine. Since my motor was from a manual trans kick, I had to go to u pull it yard and find a double pulley part to attach to the throttle body so my tv cable can be hooked up. Length wasn't any issue.

Its just getting it adjusted correctly so it functions properly that takes some time. I also used the stock kick shifter.

I also filed down the reverse gate so I can hit reverse quickly when needed. And it has its fair share of times used. I simply made a little box to cover it. I made a stubby intermediate shaft as well.

Same basic yolk to yolk similar to what you did. Mine has 5 years and lots of high speed and road miles on it and its vibration free.

Transmission Repair Manual

My flanges and yolks were in real good shape and used the higher dollar oem style ujoints in mine. Since my motor was from a manual trans kick, I had to go to u pull it yard and find a double pulley part to attach to the throttle body so my tv cable can be hooked up. Length wasn't any issue. Its just getting it adjusted correctly so it functions properly that takes some time. I also used the stock kick shifter. I also filed down the reverse gate so I can hit reverse quickly when needed. And it has its fair share of times used.

I simply made a little box to cover it. I also need that double pully for the throttle body, i re-routed the cable up over the shift cable on the trans so it is plenty long now.

I may still fab a bracket on the gas pedal for the TV. The tail shaft on mine has some slop in it, is this normal?

Is the shaft supported by the slip yoke on the intermediate?

We have made it easy for you to find a PDF Ebooks without any digging. And by having access to our ebooks online or by storing it on your computer, you have convenient answers with. To get started, you are right to find our website which has a comprehensive collection of manuals listed. Our library is the biggest of these that have literally hundreds of thousands of different products represented. easily to access, read and get to your devices. This ebooks document is best solution for you.

A copy of the instructions for digital format from original resources. Using these online resources, you will be able to find just about any form of manual, for almost any product.

Transmission Automatic

Additionally, they are entirely free to find, so there is totally free (read cloudamericainc-library.com: privacy policy). File Name Size Status.pdf 56543 KB AVAILABLE Click the button or link below to register a free account.